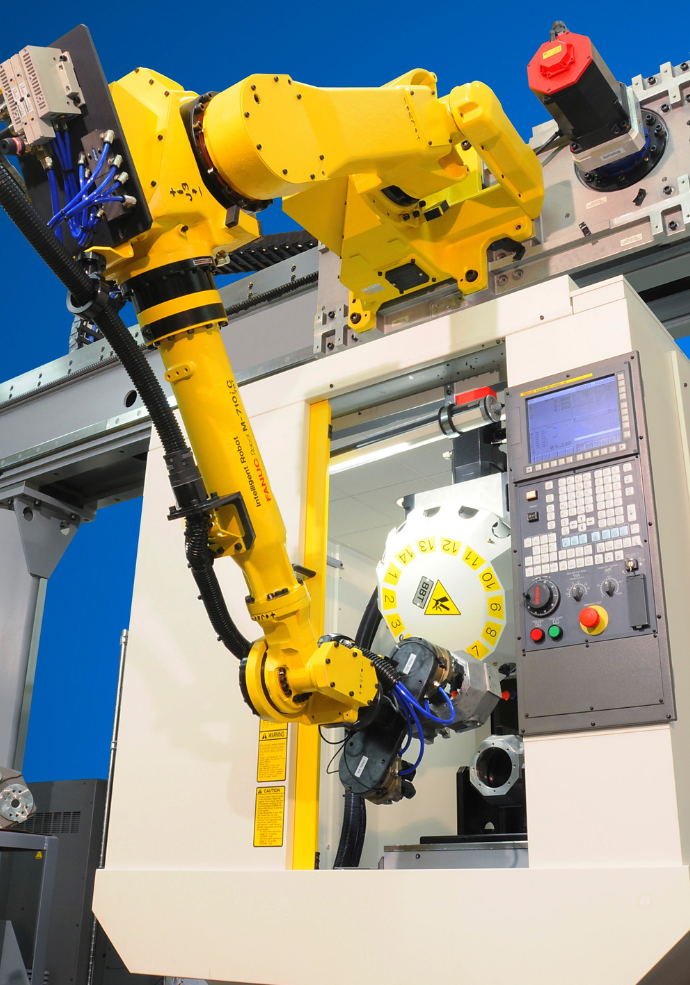

Robotic arms, at the center of modern production and manufacturing change the rules in a way that was previously impossible. They are able to combine precision, safety and efficiency. These amazing machines, commonly called robot arms, are indispensable in the global manufacturing industry driven by the urgent necessity to cut operating costs while ensuring high standards of quality. Integrating robotic arms into production line allows manufacturers to not only reduce costs, but also increase worker safety and efficiency. Learn how these cutting-edge robotics have changed the landscape of industrial production.

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. Owners of factories are under constant stress to prevent workplace injuries, limit manufacturing errors, and decrease costs. Robotic arms face these issues head-on. In contrast to human workers, robotic arms are able to perform routine tasks with precision which eliminates costly errors and reducing raw material wastage. For example, in industries with high volumes such as automotive manufacturing, robotic arms perform precise welding and parts placement, ensuring flawless assembly every time. This precision results in significant savings, as less defects mean less rework, waste and work.

Safety is a further pillar of the robot arm revolution. Human workers are at risk when performing many manufacturing tasks, such as handling dangerous materials or operating heavy machinery. With the help of robot arms, businesses can eliminate employees from hazardous environments, significantly decreasing the risk of workplace injuries. Robotic arms consist from a set of moveable joints that mimic human arm’s functionality. They operate without any danger of injuries. They are equipped with robotic hands or end-effectors that can be programmed. They are capable of performing tasks such as grasping, spinning, and welding in conditions that would make it unsafe for humans.

The versatility of robot arms can be a game changer in many industries. Robots are able to adapt to many different tasks, from automotive assembly to electronic production. Because they are programmeable, they can to perform complex operations, such as tending machines paint, or fiberglass applications, with a remarkable accuracy. When it comes to warehousing robotic arms have changed palletizing by making it easier to load items onto pallets with accuracy and speed. Automation does not just increase efficiency however, it also improves reliability because robot arms are able to perform their work without fatigue.

One of the most intriguing innovations in this area is the rise of collaborative robots, also known as cobots. These robots collaborate with human employees. Cobots, that are outfitted with a robotic arm interact seamlessly with humans unlike industrial robots which are normally restricted to cells. Cobots with robotic arms can perform difficult or repetitive lifting tasks in a factory and allow human workers to concentrate on more difficult responsibilities. This type of collaboration boosts productivity and maintains a safe workplace since cobots may be programmed so that they can adjust or stop their movements if someone is nearby.

The effects of robotic arms go beyond safety and efficiency to the very core of manufacturing today. The ability robotic arms to carry out tasks with incredible precision, such as welding, material handling, or assembly is what makes them essential in fields where safety is a priority. For example, in manufacturing of automobiles, a robot arm is able of rotating and repositioning parts during assembly, ensuring flawless alignment, without the intervention of humans. Similarly, in electronics, robot arms manage delicate components using care, minimizing damages and improving the quality of output.

As industries continue to grow, the role of robotic arms will continue to grow. The ability of robot arms to reduce costs, improve safety and be flexible to various tasks positions them as an integral part of manufacturing’s future. Combining cutting-edge technology and human ingenuity robot arms are more than just tools. They are partners that drive innovation, transforming how we create our world.